Kawasaki Heavy Industries, Ltd.

1-14-5, Kaigan, MInato-ku, Tokyo Japan, 105-8315 JAPAN

Corporate information

| Address | 105-8315 1-14-5, Kaigan, MInato-ku, Tokyo Japan, 105-8315 JAPAN |

|---|---|

| TEL | +81-34352374 |

| URL | https://global.kawasaki.com/en/ |

| mizutani_s@global.kawasaki.com |

Product introduction

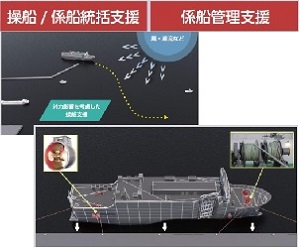

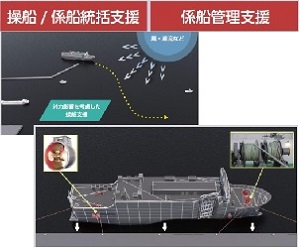

Safe Berthing/Unberthing Assist System

Kawasaki Heavy Industries, Ltd. has merged own propulsion integrated system and mooring support system to offer the new system designed to facilitate automatic maneuvering and mooring in order to enhance both safety and efficiency for in-port vessel maneuvering, berthing/unberthing, and mooring operations.

Kawasaki Electric and Hybrid Propulsion Systems

Our Electric and Hybrid Propulsion systems allow vessels to reduce exhaust gas emissions and minimize energy consumption for propulsion and hotel load. This is achieved through a unique, highly integrated design that incorporates multiple energy sources and specialized marine machinery products customized to the specific requirements of each vessel's operations.

Mooring Tension Monitoring System

There is no quantitative method for checking the tension of the mooring line in the sense of the seafarer. The developed product can quantify and monitor tension by adopting a sensor for the brake of the mooring machine. It is also expected to improve ship management by improving safety and labor saving.

SOPass

Catering to everyone who is engaged in voyage management onshore, our voyage performance management system supports the full spectrum of your fleet operation. With SOPass, data collected from vessels are not only analyzed and visualized, but also utilized for future forecasting so you will improve optimizing voyage plans. For anyone who wants safer voyages with less cost, SOPass is here for you!

Condition Monitoring System

This is a system that sends data on various propulsion equipment installed on board to shore to monitor the operating status of the equipment. By using the collected data, it contributes to monitoring the operating status, supporting safe navigation of the vessel, and achieving optimal operation.

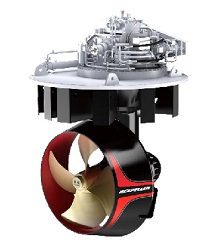

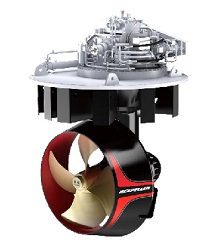

Propulsion System (CPP, Side Thruster, Steerable Thruster, KICS)

In 1956, Kawasaki Heavy Industries, Ltd. started the manufacturing of Controllable Pitch Propeller on the technologies earned experience of shipbuilding and advanced hydraulic control technology. Kawasaki has developed Side Thruster, Steerable Thruster (Rexpeller) and KICS.

Green Gas Engine

Kawasaki developed marine pure gas engine, Kawasaki Green Gas Engine, model L30KG series by original standout technology. It can effectively reduce the amount of NOx to comply with IMO TierIII regulation and minimizes CO2 by lean-burn technology.

E-series Steering Gear Unified-Edition

This time, we offer a new Steering Gear aimed at optimization. We can design and package complex steering systems together to efficiently procure and troubleshoot steering rooms.

Steering Gear & Deck Machinery

In 1916, the company began manufacturing steering Gear pumps based on the advanced hydraulic control technology it had accumulated over many years. Since then, we have been manufacturing "steering Gears" and "deck machines".

Product introduction

| Safe Berthing/Unberthing Assist System |

Kawasaki Heavy Industries, Ltd. has merged own propulsion integrated system and mooring support system to offer the new system designed to facilitate automatic maneuvering and mooring in order to enhance both safety and efficiency for in-port vessel maneuvering, berthing/unberthing, and mooring operations. | |

Kawasaki Electric and Hybrid Propulsion Systems | |

Our Electric and Hybrid Propulsion systems allow vessels to reduce exhaust gas emissions and minimize energy consumption for propulsion and hotel load. This is achieved through a unique, highly integrated design that incorporates multiple energy sources and specialized marine machinery products customized to the specific requirements of each vessel's operations. | |

| Mooring Tension Monitoring System |

There is no quantitative method for checking the tension of the mooring line in the sense of the seafarer. The developed product can quantify and monitor tension by adopting a sensor for the brake of the mooring machine. It is also expected to improve ship management by improving safety and labor saving. | |

SOPass | |

Catering to everyone who is engaged in voyage management onshore, our voyage performance management system supports the full spectrum of your fleet operation. With SOPass, data collected from vessels are not only analyzed and visualized, but also utilized for future forecasting so you will improve optimizing voyage plans. For anyone who wants safer voyages with less cost, SOPass is here for you! | |

| Condition Monitoring System |

This is a system that sends data on various propulsion equipment installed on board to shore to monitor the operating status of the equipment. By using the collected data, it contributes to monitoring the operating status, supporting safe navigation of the vessel, and achieving optimal operation. | |

| Propulsion System (CPP, Side Thruster, Steerable Thruster, KICS) |

In 1956, Kawasaki Heavy Industries, Ltd. started the manufacturing of Controllable Pitch Propeller on the technologies earned experience of shipbuilding and advanced hydraulic control technology. Kawasaki has developed Side Thruster, Steerable Thruster (Rexpeller) and KICS. | |

| Green Gas Engine |

Kawasaki developed marine pure gas engine, Kawasaki Green Gas Engine, model L30KG series by original standout technology. It can effectively reduce the amount of NOx to comply with IMO TierIII regulation and minimizes CO2 by lean-burn technology. | |

| E-series Steering Gear Unified-Edition |

This time, we offer a new Steering Gear aimed at optimization. We can design and package complex steering systems together to efficiently procure and troubleshoot steering rooms. | |

| Steering Gear & Deck Machinery |

In 1916, the company began manufacturing steering Gear pumps based on the advanced hydraulic control technology it had accumulated over many years. Since then, we have been manufacturing "steering Gears" and "deck machines". | |

Exhibitors in the same category