TOCALO CO.,LTD.

6-4-4, Minatojimaminami-Machi, Chuo-Ku, Kobe, Hyogo JAPAN

Corporate information

| Address | 650-0047 6-4-4, Minatojimaminami-Machi, Chuo-Ku, Kobe, Hyogo JAPAN |

|---|---|

| TEL | +81-78-303-3455 |

| URL | https://www.tocalo.co.jp/english/ |

| kaitsunehiro@tocalo.co.jp |

Sharing Exhibitor

- Japan Coating Center Co., Ltd.(JAPAN)

Product introduction

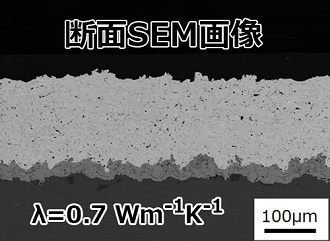

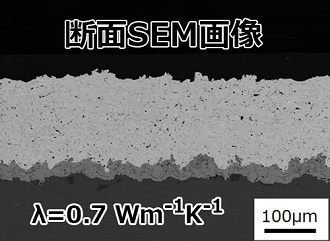

Development of new thermal barrier coatings

We have developed a coating that is denser and has lower thermal conductivity than conventional heat-shielding coatings (8YZ: partially stabilized zirconia). For example, coating the inner wall of the combustion chamber of an engine can be expected to improve thermal efficiency.

SLC-2 coating with ultra-low friction and excellent seizure resistance

We have developed SLC-2, a Pb-free Cu alloy-based coating with ultra-low friction and high seizure resistance. SLC-2 exhibits low friction and high seizure resistance compared to lead bronze castings such as CAC603.

"T-8ER7" film with high cavitation erosion resistance

We have developed T-8ER7, a coating with high cavitation erosion resistance. This coating is applied by laser cladding, which requires less heat input to the base material and reduces base material distortion compared to conventional welding methods.

Super ZAC coating with high corrosion resistance

Super ZAC is a dense ceramic coating that can be applied to the interior and exterior surfaces of small-diameter piping. Since the film is composed of stable oxides, it can be applied as a corrosion-resistant coating to protect base materials from acids such as sulfuric acid.

"EF-JET" alternative coating to Cr plating

High hardness thin film coating "EF-JET" shows higher abrasion resistance than hard chrome plating while the film thickness is equivalent to that of hard chrome plating. Compared to conventional thermal spray coatings, EF-JET is denser and can be applied to thin film finishes.

Self-fluxing alloy spraying "SDC-LA1" with ultra-thick film

Thick film thickness of more than 4 mm has been achieved in self-fluxing alloy spraying with high hardness and high toughness. It is expected to be applied to applications in high-load environments, which have been difficult to apply with conventional thermal spraying.

"T-4318" sediment and abrasion resistant coating

Damage due to sediment abrasion is a problem for parts such as runners, casings, and impellers used in slurry conveying pumps. "T-4318" improves resistance to sediment abrasion and is effective in extending the service life of pump parts.

Wear-resistant coatings on CFRP components

Replacing metal components with CFRP can be expected to improve efficiency by reducing weight, but it is inferior in wear resistance. Therefore, the application of cemented carbide spraying to the surface of CFRP significantly improves wear resistance and is effective in reducing running costs.

Coating heaters that spray directly onto the object to be heated

Since the thermal spray heater is applied directly to the object to be heated, the contact area is large and heat loss is small, allowing energy to be used without waste. In addition, high heat uniformity can be achieved by designing a pattern suitable for the shape of the object to be heated.

Hard thin film "TD-VC coating" with abrasion and seizure resistance

TD-VC is an extremely hard film that protects the base material by preventing wear and burning. Since TD-VC is applied by the salt bath treatment method, it can be applied uniformly regardless of the shape of the workpiece, including internal surfaces and blind spots.

Product introduction

| Development of new thermal barrier coatings |

We have developed a coating that is denser and has lower thermal conductivity than conventional heat-shielding coatings (8YZ: partially stabilized zirconia). For example, coating the inner wall of the combustion chamber of an engine can be expected to improve thermal efficiency. | |

| SLC-2 coating with ultra-low friction and excellent seizure resistance |

We have developed SLC-2, a Pb-free Cu alloy-based coating with ultra-low friction and high seizure resistance. SLC-2 exhibits low friction and high seizure resistance compared to lead bronze castings such as CAC603. | |

| "T-8ER7" film with high cavitation erosion resistance |

We have developed T-8ER7, a coating with high cavitation erosion resistance. This coating is applied by laser cladding, which requires less heat input to the base material and reduces base material distortion compared to conventional welding methods. | |

| Super ZAC coating with high corrosion resistance |

Super ZAC is a dense ceramic coating that can be applied to the interior and exterior surfaces of small-diameter piping. Since the film is composed of stable oxides, it can be applied as a corrosion-resistant coating to protect base materials from acids such as sulfuric acid. | |

| "EF-JET" alternative coating to Cr plating |

High hardness thin film coating "EF-JET" shows higher abrasion resistance than hard chrome plating while the film thickness is equivalent to that of hard chrome plating. Compared to conventional thermal spray coatings, EF-JET is denser and can be applied to thin film finishes. | |

| Self-fluxing alloy spraying "SDC-LA1" with ultra-thick film |

Thick film thickness of more than 4 mm has been achieved in self-fluxing alloy spraying with high hardness and high toughness. It is expected to be applied to applications in high-load environments, which have been difficult to apply with conventional thermal spraying. | |

| "T-4318" sediment and abrasion resistant coating |

Damage due to sediment abrasion is a problem for parts such as runners, casings, and impellers used in slurry conveying pumps. "T-4318" improves resistance to sediment abrasion and is effective in extending the service life of pump parts. | |

| Wear-resistant coatings on CFRP components |

Replacing metal components with CFRP can be expected to improve efficiency by reducing weight, but it is inferior in wear resistance. Therefore, the application of cemented carbide spraying to the surface of CFRP significantly improves wear resistance and is effective in reducing running costs. | |

| Coating heaters that spray directly onto the object to be heated |

Since the thermal spray heater is applied directly to the object to be heated, the contact area is large and heat loss is small, allowing energy to be used without waste. In addition, high heat uniformity can be achieved by designing a pattern suitable for the shape of the object to be heated. | |

| Hard thin film "TD-VC coating" with abrasion and seizure resistance |

TD-VC is an extremely hard film that protects the base material by preventing wear and burning. Since TD-VC is applied by the salt bath treatment method, it can be applied uniformly regardless of the shape of the workpiece, including internal surfaces and blind spots. | |

Sharing Exhibitor

Exhibitors in the same category