Headway Technology Group (Qingdao) Co., Ltd.

#32 Keyuan Jing 6th Road, Qingdao 266100 P.R. China CHINA

Corporate information

| Address | 266100 #32 Keyuan Jing 6th Road, Qingdao 266100 P.R. China CHINA |

|---|---|

| TEL | +86-532-8578-8888 |

| URL | http://en.headwaytech.com/ |

| kris.kang@headwaytech.com |

Contact in Japan

| Japan agent | HEADWAY TECHNOLOGY GROUP |

|---|---|

| kris.kang@headwaytech.com |

Product introduction

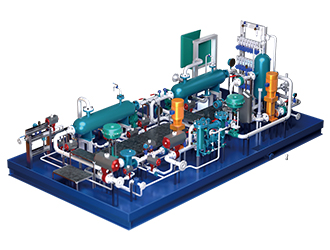

OceanGuard® Methanol Fuel Supply System

OceanGuard® Methanol Fuel Supply System(LFSS), independently developed by Headway Technology Group, is adaptable for both ocean-going and inland waterway vessels. By effectively adjusting the backflow, the module promptly regulates the pressure and flow rate of methanol fuel, ensuring optimal performance and precise control in fuel supply operations. The system has obtained two orders in 2023 and receive high recognition from customers and more orders are on the way.

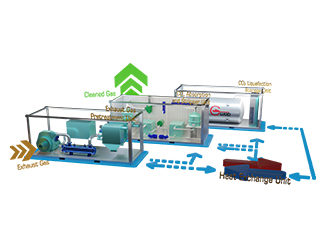

OceanGuard® Exhaust Gas Cleaning System

OceanGuard® Exhaust Gas Cleaning System have concluded excellent resource of the whole industry chain to meet the requirement of customers. According to the director of EGCS team, Headway is capable of providing both Open Loop and Closed Loop solution to customers. Furthermore, Headway has been providing Open Loop solutions with "Hybrid Ready" design, which ensures the delivered Open Loop system can be upgraded into a Hybrid system without dry-docking.

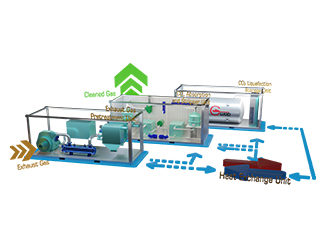

Oceanguard® Carbon Capture Utilization and Storage

Oceanguard® CCUS adopts Headway's self-developed high-efficiency decarbonizer and high-speed centrifugal decarburization technology. It can not only avoid the inconvenience of large size and high energy consumption of traditional decarbonization scrubber, but also achieve a carbon dioxide removal efficiency of more than 80%, and the purity of carbon dioxide after liquefaction of more than 99.6%. The system has been already approved by DNV, RINA, CCS and other major classification societies.

OceanGuard® Ballast Water Management System

OceanGuard® BWMS adopts patented AEOP to treat ballast water which ensures mainstream single treatment of all type ballast water without hydrogen generation corrosion. With more than 3500 shipsets orders, Headway, holding the Independent Intellectual Property of filter, is one of the major manufactures in the world. It is developed specially for ballast water treatment and has been proven by independent laboratories and shipowners as a reliable solution even in extreme conditions.

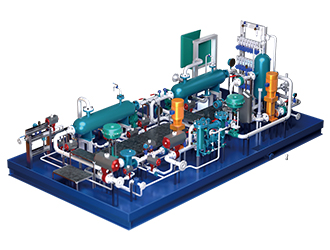

OceanGuard® Fuel Gas Supply Syste

OceanGuard® FGSS compatible with various types of dual fuel medium to low-speed engines, inland river marine dual-fuel engines and generators from major manufacturers. The whole gas process package adopts customized development / modular design, and the layout is optimized according to the ship arrangement. The main control system and safety system adopt a redundant diversity structure, which enables the equipment to detect its working status at any time.

Product introduction

| OceanGuard® Methanol Fuel Supply System |

OceanGuard® Methanol Fuel Supply System(LFSS), independently developed by Headway Technology Group, is adaptable for both ocean-going and inland waterway vessels. By effectively adjusting the backflow, the module promptly regulates the pressure and flow rate of methanol fuel, ensuring optimal performance and precise control in fuel supply operations. The system has obtained two orders in 2023 and receive high recognition from customers and more orders are on the way. | |

| OceanGuard® Exhaust Gas Cleaning System |

OceanGuard® Exhaust Gas Cleaning System have concluded excellent resource of the whole industry chain to meet the requirement of customers. According to the director of EGCS team, Headway is capable of providing both Open Loop and Closed Loop solution to customers. Furthermore, Headway has been providing Open Loop solutions with "Hybrid Ready" design, which ensures the delivered Open Loop system can be upgraded into a Hybrid system without dry-docking. | |

| Oceanguard® Carbon Capture Utilization and Storage |

Oceanguard® CCUS adopts Headway's self-developed high-efficiency decarbonizer and high-speed centrifugal decarburization technology. It can not only avoid the inconvenience of large size and high energy consumption of traditional decarbonization scrubber, but also achieve a carbon dioxide removal efficiency of more than 80%, and the purity of carbon dioxide after liquefaction of more than 99.6%. The system has been already approved by DNV, RINA, CCS and other major classification societies. | |

| OceanGuard® Ballast Water Management System |

OceanGuard® BWMS adopts patented AEOP to treat ballast water which ensures mainstream single treatment of all type ballast water without hydrogen generation corrosion. With more than 3500 shipsets orders, Headway, holding the Independent Intellectual Property of filter, is one of the major manufactures in the world. It is developed specially for ballast water treatment and has been proven by independent laboratories and shipowners as a reliable solution even in extreme conditions. | |

| OceanGuard® Fuel Gas Supply Syste |

OceanGuard® FGSS compatible with various types of dual fuel medium to low-speed engines, inland river marine dual-fuel engines and generators from major manufacturers. The whole gas process package adopts customized development / modular design, and the layout is optimized according to the ship arrangement. The main control system and safety system adopt a redundant diversity structure, which enables the equipment to detect its working status at any time. | |

Exhibitors in the same category