SPECS Corporation

Bundang Techno-Park Bldg. B-7th Floor, 723 Pangyo-ro, Bundang, Gyeonggi 13511 紹介動画: https://www.youtube.com/watch?v=F-wTvN-W008&t

1-5 Nishihira-cho, Nishinomiya-city, Hyogo Pref. 662-0093, JAPAN

企業情報

| 住所 | 〒13511 Bundang Techno-Park Bldg. B-7th Floor, 723 Pangyo-ro, Bundang, Gyeonggi 13511 |

|---|---|

| TEL | +82-31-706-5211 |

| URL | http://www.specs.co.kr/ |

| specs@specs.co.kr |

日本におけるコンタクト先

| 代理店名 | NAR Corporation |

|---|---|

| 住所 | 〒662-0093 1-5 Nishihira-cho, Nishinomiya-city, Hyogo Pref. 662-0093, JAPAN |

| TEL | +81-798-73-0593 |

| ishihara@nar-corp.co.jp |

出展製品・サービス

Oil Mist Detection System(OMD)

1.Low CAPEX/OPEX with long life span 2.Alarm instantly triggered by presence of oil mist 3.Contamination resistant 4.Robust anti-vibration assembly 5.MIL STD-167, MIL-S-901D (VISION IIIA) 6.IECEx, ATEX Certificate of Conformity (VISION 5X)

Bearing Wear Monitoring System(BWM)

1.Low CAPEX/OPEX 2.Complies with latest MES algorithm and IACS requirements 3.Most rigid structure 4.Securely access remote HMI from anywhere around the world 5.Simple installation 6.Temperature compensated sensor design

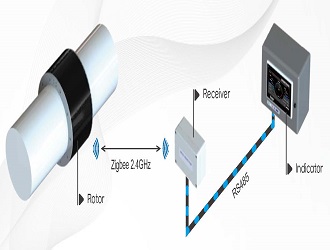

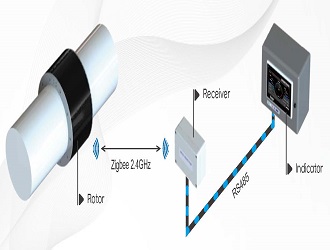

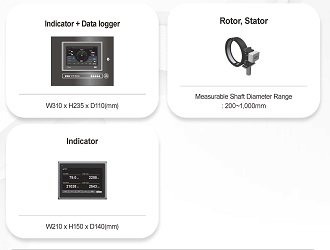

Shaft Torque Power RPM Meter(TPM)

1.Easy to install simple bracket arrangement – No shaft modifications 2.Various outputs available for all data logging requirements 3.Optional thrust measurement 4.Not affected by any pollutional or hazardous materials 5.Single or dual shaft applications 6.Maintenance free operation owing to no mechanical wear

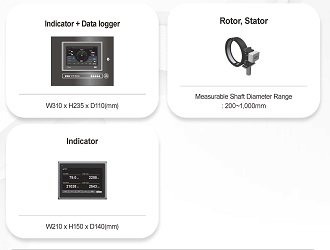

Shaft Torque Power RPM Meter(iTPM)

1.Incredible energy saving 2.Applicable to various shaft sizes from 300 to 900 mm 3.Simple installation - integration type 4.2years without battery replacement 5.Compatible with existing indicator 6.Guaranteed long life span battery

TPM SHaPoLi

1.Fully met with EEXI regulation by IMO 2.No mechanical change 3.Simple installation 4.Tamperproof event and data logging (18 months storage capacity) 5.Enables integration and scalability with CII monitoring systems 6.Visible and audible alarms during override operation

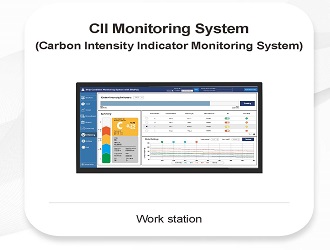

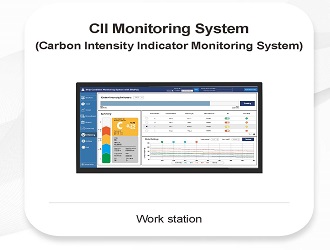

CII Monitoring System

1.Carbon Intensity Indicator data collection 2.Real-time monitoring 3.On board modem for internet access 4.Ship performance analytics 5.User-friendly interface

出展製品・サービス

| Oil Mist Detection System(OMD) |

1.Low CAPEX/OPEX with long life span 2.Alarm instantly triggered by presence of oil mist 3.Contamination resistant 4.Robust anti-vibration assembly 5.MIL STD-167, MIL-S-901D (VISION IIIA) 6.IECEx, ATEX Certificate of Conformity (VISION 5X) | |

| Bearing Wear Monitoring System(BWM) |

1.Low CAPEX/OPEX 2.Complies with latest MES algorithm and IACS requirements 3.Most rigid structure 4.Securely access remote HMI from anywhere around the world 5.Simple installation 6.Temperature compensated sensor design | |

| Shaft Torque Power RPM Meter(TPM) |

1.Easy to install simple bracket arrangement – No shaft modifications 2.Various outputs available for all data logging requirements 3.Optional thrust measurement 4.Not affected by any pollutional or hazardous materials 5.Single or dual shaft applications 6.Maintenance free operation owing to no mechanical wear | |

| Shaft Torque Power RPM Meter(iTPM) |

1.Incredible energy saving 2.Applicable to various shaft sizes from 300 to 900 mm 3.Simple installation - integration type 4.2years without battery replacement 5.Compatible with existing indicator 6.Guaranteed long life span battery | |

| TPM SHaPoLi |

1.Fully met with EEXI regulation by IMO 2.No mechanical change 3.Simple installation 4.Tamperproof event and data logging (18 months storage capacity) 5.Enables integration and scalability with CII monitoring systems 6.Visible and audible alarms during override operation | |

| CII Monitoring System |

1.Carbon Intensity Indicator data collection 2.Real-time monitoring 3.On board modem for internet access 4.Ship performance analytics 5.User-friendly interface | |

同じカテゴリーの企業