F-63 |

TOCALO Co.,Ltd.

TOCALO commands top market share in Japan with leading surface modification technology featuring our unique thermal spraying technology meeting customer specifications in all fields and industries.

Our highly refined surface modification technologies offer functions, such as heat, corrosion, and wear resistance, that reduce greenhouse gas emissions by lowering energy consumption, and reduce the consumption of resources by extending the useful life of parts and products.

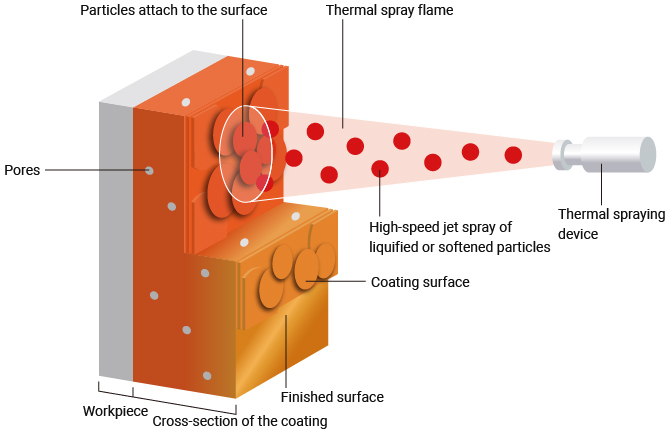

| Thermal Spray “Thermal Spray” is our core technology. In the process of spraying, metal or ceramics materials are melted by various heat sources, and sprayed onto the objects to form highly functional coatings. Surface modification technology has become integral to core industries, such as electric power plants, steel works, automobiles, and industrial machinery, as well as to high-tech industries like semiconductors, flat panel displays, space development, and advanced medicine. |

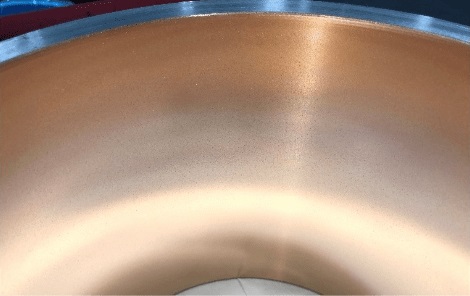

| "Carbon Fiber Reinforced Plastics + Thermal Spray" : Reducing the weight of rotating parts Carbon fiber-reinforced polymer (CFRP) contributes to preventing global warming because it is lighter than metal and requires less energy to move and rotate. However, CFRP cannot replace some metal rotating parts because they must be highly wear-resistant. TOCALO has the technology to spray CFRP parts with a hard cermet alloy coat and mirror-finish, creating CFRP rotating parts that are high-durability, lightweight, and energy efficient. |

| Aircraft parts, Engine parts Thermal spraying is applied to moving and stationary blades in jet engines for heat resistance, and to landing gear and other parts to prevent sliding wear. |

| Restoring functionality with a fresh coating (Dimensional restoration) TOCALO’s surface modification technology conserves resources and reduces waste by adding various functions and extending the life of machine parts. In addition, machine parts with coatings that have become worn and have reduced functionality due to extensive use can often be restored to full functionality by applying a fresh coating. Applying a new coat to machine parts eliminates the need to replace the parts and reduces the consumption of resources. |

| Laser cladding process (TOCALO Laser Clad) TOCALO Laser Clad (TLC) is an overlaying technology using the laser beam for its heat source. In the process, the powder material is fed into the focal point of the laser beam to melt the material and form overlay depositions on the base material surface. TLC has a low heat input, so it has less thermal effects on the base metal than other welding methods. |

| Sleeves (Frictional parts) In many cases, thermal spraying the sliding parts of sleeves can eliminate the need for lubrication when operating machine equipment with the significant benefits of improving environmental performance, reducing the cost of consumables, and protecting products from foreign matter. |

| Pump components TOCALO ceramic coating is used in various pump components to provide erosion resistance, improve durability, and extend component life. |

| Pipework (hydrogen embrittlement resistance) TOCALO's MS-ZAC technology reduces tritium permeation while also protecting against hydrogen embrittlement. We are continuing to develop the technology to provide solutions for the growing use of hydrogen in society. |

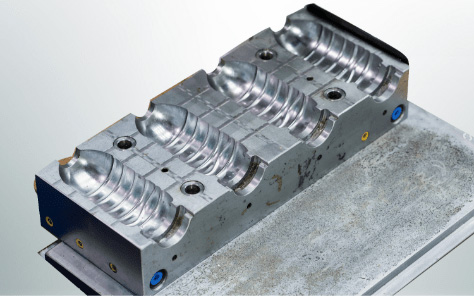

| Demolding property / Water repellency (Ex. Injection molding) Coatings can provide demolding properties to resin mold and metal casting dies by using materials that are incompatible with the casting material. When using a viscous material that comes into contact with specific part, it is also possible to reduce adhesiveness by making the points of contact smaller. Coatings also provide solutions for productivity loss due to material residue on parts that come in contact with paint or oil. |

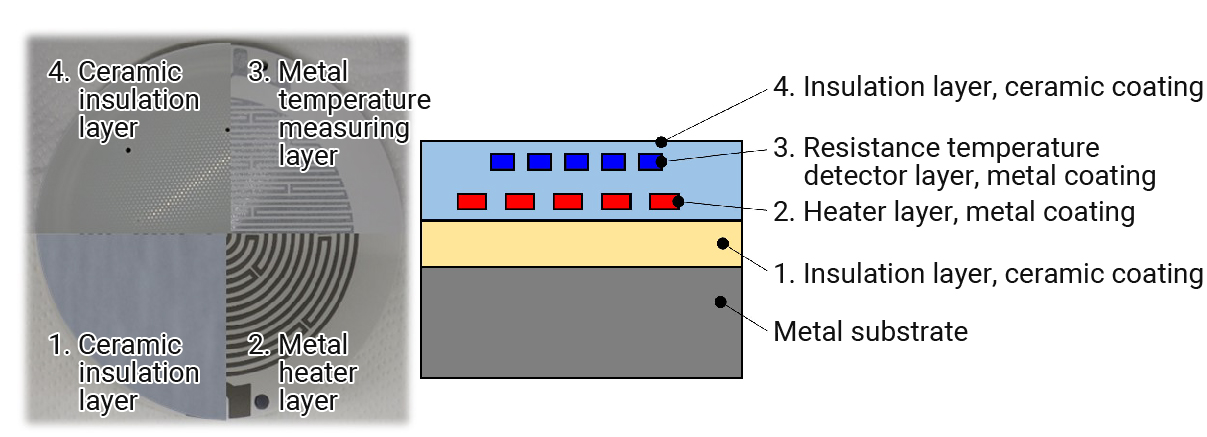

| Thermal Spray Heater Heaters of desired watt density can be produced by spraying heating elements directly on substrate. “Thermal Spray Heater” has an excellent heating efficiency due to its large surface area and small heat loss. Most of resistive materials can be thermal sprayed to form heaters. |

Corporate information

| Address | 711-0935 2030-28, kojima-unotsu, Kurashiki-City, Okayama JAPAN |

|---|---|

| TEL | +81-64703433 |

| URL | https://www.tocalo.co.jp/english/ |