F-67 |

TOCALO Co.,Ltd.

| New Thermal Barrier Coating We have developed a denser, lower thermal conductivity coating compared to conventional thermal barrier coatings (8YZ: partially stabilized zirconia). For example, applying this coating to the inner walls of an engine combustion chamber can improve thermal efficiency. |

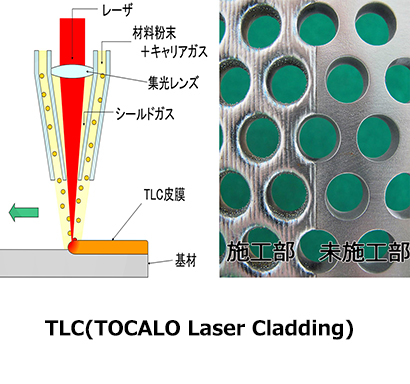

| TLC Repair Technology The TLC technology is characterized by low heat input and minimal thermal distortion. It enables overlay welding for coating and repair on components that were previously unsuitable for conventional welding processes. Additionally, it allows for internal diameter repairs on cylindrical parts with a diameter of 50 mm or larger. |

| T-8ER7 We have developed "T-8ER7," a coating with excellent cavitation erosion resistance. Our laser cladding technology features low heat input and minimal thermal distortion. This enables coating and repair through buildup welding on components that could not be processed using conventional welding methods. For cylindrical parts with an inner diameter of at least φ50mm, internal surface repairs are also possible. |

| SUPER ZAC SUPER ZAC features excellent corrosion resistance. It forms a dense ceramic film that can be applied to both the inner and outer surfaces of piping. Composed of stable oxides, the coating serves as an effective corrosion-resistant barrier, protecting the substrate from acids such as sulfuric acid. |

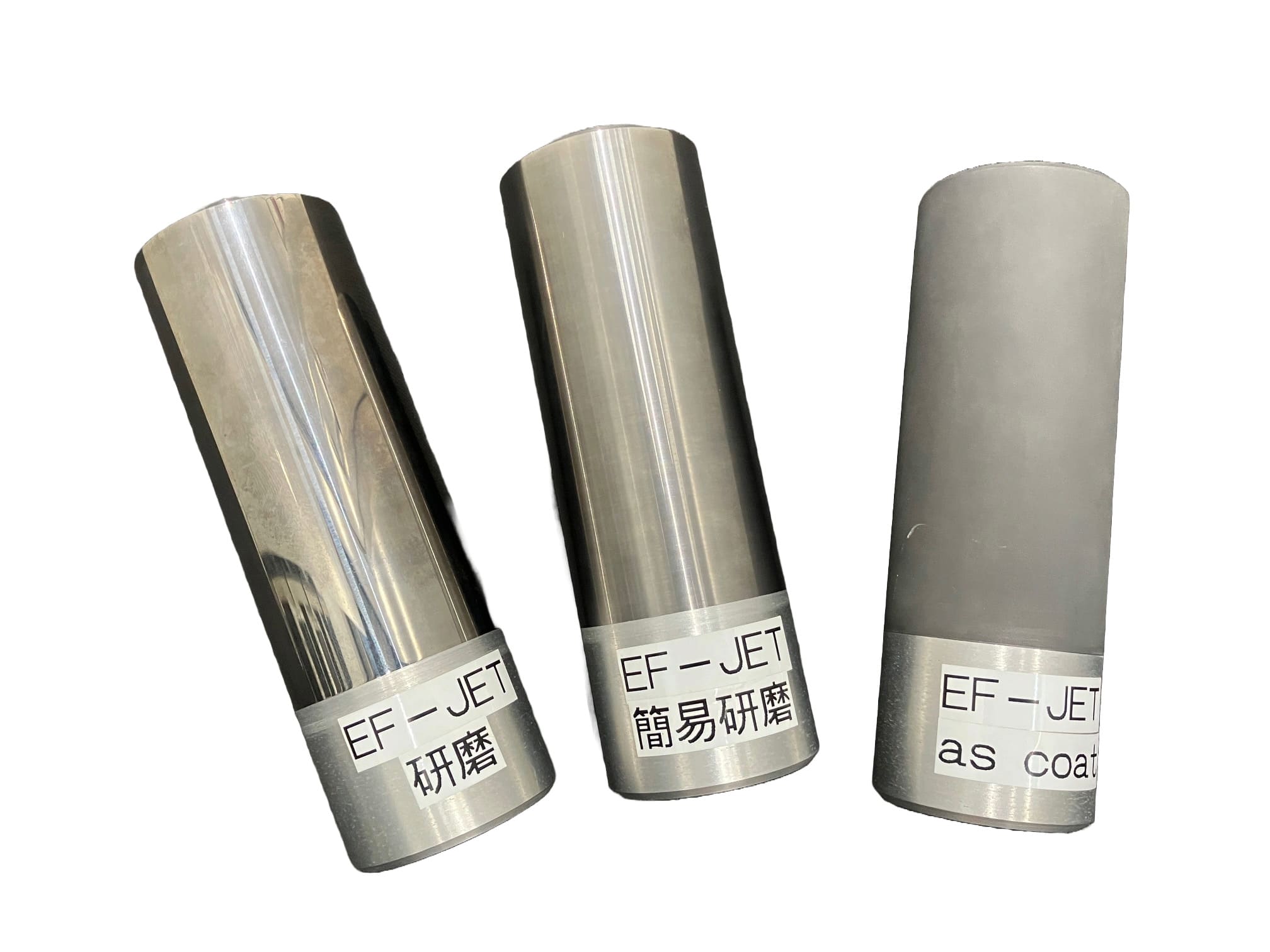

| EF-JET Coating The high-hardness thin-film coating "EF-JET" has a thickness comparable to that of hard chrome plating but offers superior wear resistance. Compared to conventional thermal spray coatings, it is denser and allows for a thin-film finish. |

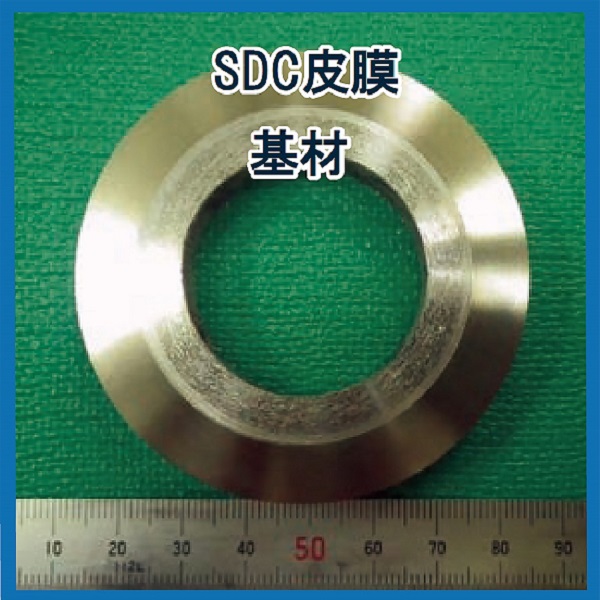

| Self-fluxing alloy spraying "SDC-LA1" SDC-LA1 is a high-hardness thermal spray coating made of self-fluxing alloy, offering excellent toughness. Our company has achieved a coating thickness of over 4 mm. It is expected to be applicable to demanding environments that were difficult to apply with conventional thermal spraying. |

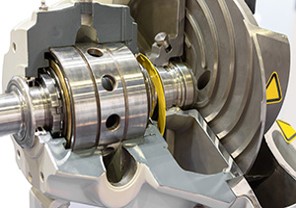

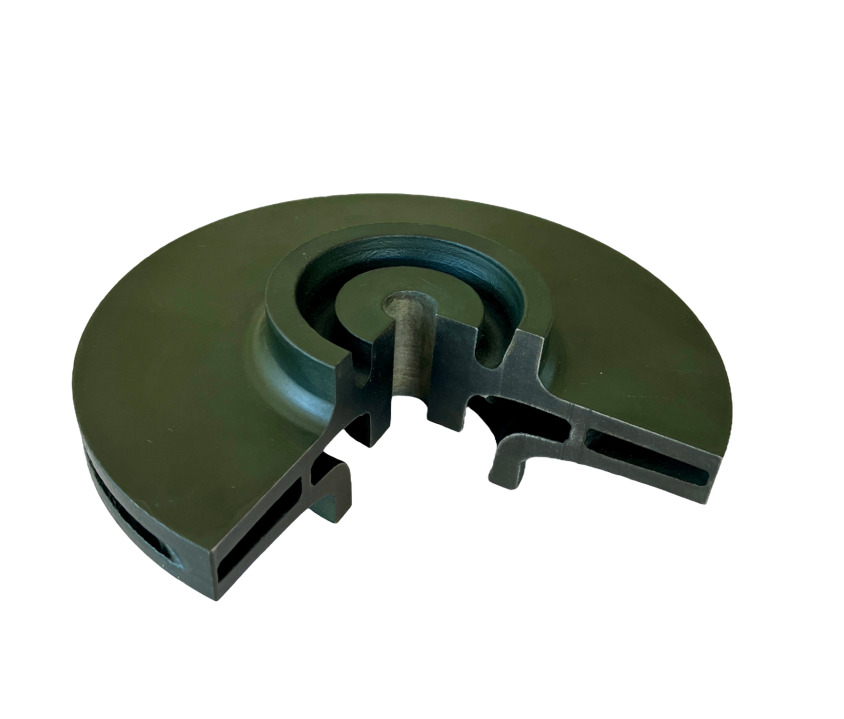

| Sand Abrasion Resistant Coating "T-4318" Components such as runners, casings, and impellers used in slurry transport pumps are prone to damage from sand abrasion. "T-4318" improves sand abrasion resistance, making it effective in extending the service life of pump components. |

| MS-ZAC MS-ZAC is a dense ceramic film that can be applied to both the inner and outer surfaces of piping. It suppresses hydrogen permeation in high-temperature environments, reducing hydrogen embrittlement of metal materials. Additionally, it serves as a corrosion-resistant coating that protects the substrate from acids such as sulfuric acid. |

| Thermal Spray Heater By forming a thermal spray heater on the surface of the heated object, heat can be applied directly, ensuring efficient energy utilization with minimal waste. Additionally, by designing a pattern that matches the shape of the heated object, high thermal uniformity can be achieved. |

| NP-kote NP-kote can be applied over large areas without the use of volatile organic compounds (VOCs) or a heat source for curing, making on-site application possible. The highly elastic coating provides excellent impact resistance and demonstrates superior erosion resistance against powder particles. |

Corporate information

| Address | 6-4-4 6-4-4, Minatojimaminami-Machi, Chuo-Ku, Kobe, Hyogo JAPAN |

|---|---|

| TEL | +81-78-303-3455 |

| URL | https://www.tocalo.co.jp/english/ |