C2-14 |

Kranendonk Japan B.V.

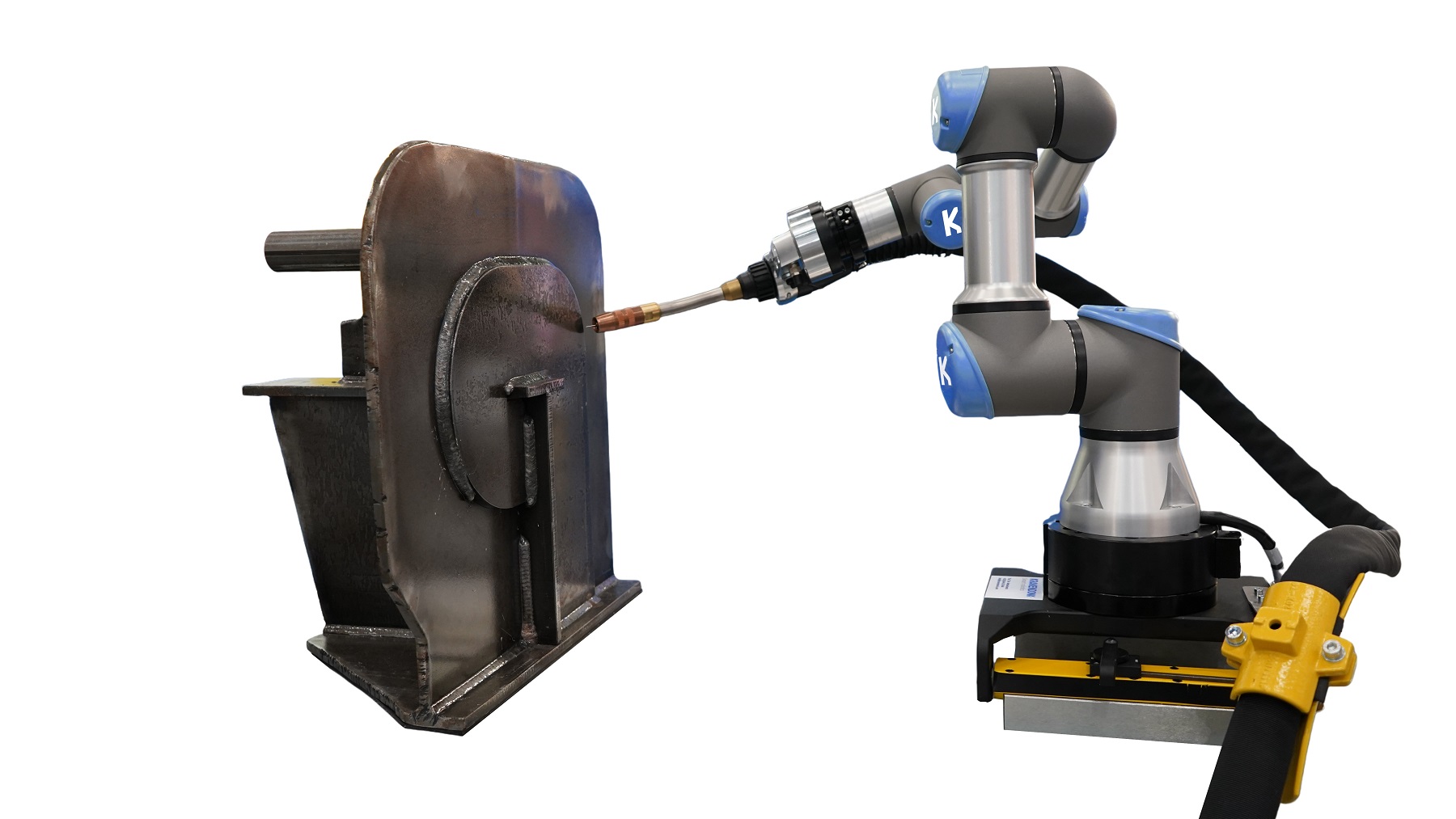

| Portabot: Portable Welding Robot KRANENDONK has developed the "PortaBot", a portable welding robot that simplifies complex welding work in tight spaces. It is highly automated in conjunction with 3D models, making welding precise and easy. Document Download |

Artemis: Micro Welding Gantry KRANENDONK presents the new Artemis Micro Welding Gantry with Scanning. This automatic welding system can be applied to micro panel assembly without teaching because it is programmed from the scan function, which is optimal for users who cannot prepare 3D models. |

Robotic Pipe Shop Kranendonk has robotic pipe shop specialized for bendable spools (fillet welding on pipes and flanges). Additionally, developed welding technology for non-bendable spools (butt welding with elbows and etc) and achieved the full automated pipe shop. Document Download |

Double Hull Welding Gnatry Fully automatic welding system for large hull blocks. Instead of climbing up a scaffold and having a worker bring welding equipment into the block, the robot descends into the block to do the welding. The burden on workers can be dramatically reduced. Document Download |

| ARAC5: Cell Control Software ARAC5 is cell control software that centrally controls all field devices in the Kranendonk system and also has an HMI. An optional management information dashboard allows you to manage your system with real-time data. Document Download |

| Offshore Wind Floating Structure Production Solutions KRANENDONK will utilize the know-how it has accumulated since its founding in the automated production of huge structures such as ship hulls to propose automated production solutions for floating offshore wind structures, which require the ultimate in productivity. |

Corporate information

| Address | 750-0004 Nakano-cho 11-13 (1F), Shimonoseki, Yamaguchi JAPAN |

|---|---|

| TEL | +81-83-242-5444 |

| URL | https://www.kranendonk.com/ |