F-68 |

Wärtsilä Japan Ltd.Shaft Line Solutions

The site was originally a factory belonging to Chuestu Waukesha (a specialist in propulsion equipment) and was purchased by Wärtsilä Seals & Bearings (now known as Wärtsilä Shaft Line Solutions) in 1965.

Based in Toyoma, Shaft Line Solutions Japan has engineered environmentally friendly products and solutions, including the Airguard seal and BIO seal ring - the first seal ring material specifically developed for EAL's.

In addition to Manufacturing, the site also has Engineering, Purchasing, Inspecting and Shipping functions.

| Stern tube seal A stern tube seal is a device that prevents water from entering the ship from the shaft system through the hull and prevents oil from the stern tube from leaking out of the ship and into the engine room. |

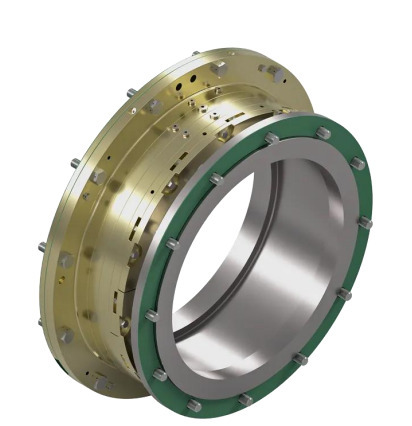

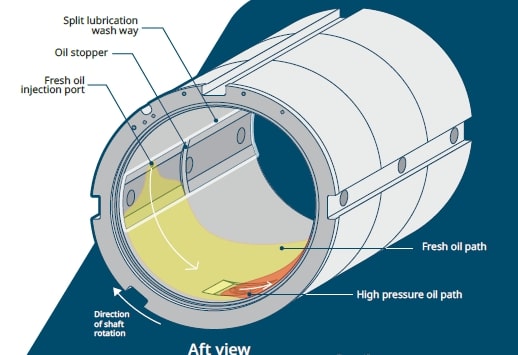

| Stern tube bearing A stern tube bearing is a bearing located inside a stern tube that supports the propeller shaft or stern tube shaft. |

| Intermediate shaft bearing The Linesafe intermediate shaft bearing consists of an equipment designed to keep aligned and support the weight of the intermediate shaft line in a vessel. The Linesafe intermediate shaft bearing can be designed in different configurations to meet the customer requirements (self-lubrication, forced-lubrication, SRtP, etc). |

| 10-Years Airguard Seal Sturn Tube seals 10-year service interval Building on proven Wärtsilä Airguard performance, the 10-Years Airguard Seal gives you a decade of operation without needing to replace seal rings. This leads to operational cost. |

| IntelliSafe Barings Next-generation bearings “Warsila IntelliSafe”. Improve on conventional bearings. • Self-regulating bearing that ensures there’s always enough lubricating oil. • More robust against unfavourable operating conditions, reducing the risk of unforeseen damages. • Eliminates metal-to-metal contact, significantly extending the bearing’s lifecycle. • Significant cost savings due to reduced damage risk and extended operating |

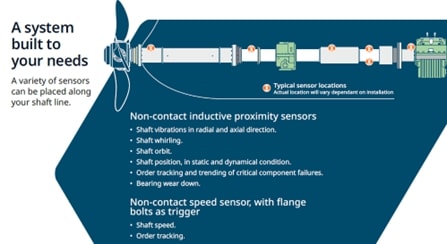

| Shaft line Monitoring system Monitoring Equipment lets you monitor conditions, detect deviations from standard operations and log results to help with preventative maintenance. A variety of sensors can be placed along your shaft line. • Shaft vibrations in radial and axial direction. • Shaft whirling. • Shaft orbit. • Shaft position, in static and dynamical condition. • Order tracking and trending of critical component failures. • Bearing wear down. • Shaft speed. |

Corporate information

| Address | 100-0013 Shin-Kasumigaseki Building 3F, 3-3-2 Kasumigaseki, Chiyoda-ku, Tokyo JAPAN |

|---|---|

| TEL | +81-3-6631-7670 |

| URL | https://www.wartsila.com/jpn |